If you’re looking at current transformers core , you truly have two options: split core transformer and strong center transformer. A contactless, split core transformer’s principle specialty is its capacity to be snapped over previous wires, making them perfect for retrofitting undertakings and that’s just the beginning. There is no compelling reason to screw or weld any kind of bracketry, so they are anything but difficult to introduce. Likewise, they can be introduced inside an electrical control boards, which enable you to stay away from complex and periodically costly wiring. They can be introduced in a live framework without the stress of meddling with its present operation, settling on it the perfect decision for engineers hoping to plan a power meter system.

Split core transformers are intended to screen an assortment of remotely found gadgets that might be situated in ranges that are out of reach or work under cruel conditions. Remotely screen gadgets that occasionally work in blocked off or unforgiving conditions.

Lamentably, the advantages that go with split core transformers are additionally joined by a less helpful component: cost. Specialists likewise view them as fairly less precise than a strong center transformer. This is the reason it is critical to comprehend the contrasts between a split center and strong center transformer before settling on the decision as to which gadget to utilize.

Split core current transformers are made similarly as a strong center transformer with one noteworthy contrast. The core is made in two particular pieces that are effectively isolated. Since the center is isolated into two separate pieces, split center transformers are liable to mistakes because of the two pieces not reaching consistently. What’s more, the auxiliary windings are not as consistently dispersed around the center as they are in strong center transformers. In light of this inadequacy, split core transformers are not the ideal decision for all applications.

There are a few unique sorts of split core transformers that can be utilized as a part of various applications. For instance, the FeSi split core transformer is one of the more moderate alternatives. In any case, it produces poor linearity, particularly at bring down streams, improving it suited for measuring high ebbs and flows just where precision isn’t as imperative as getting an unpleasant estimation of energy utilization. These transformers are likewise cumbersome and substantial, implying that it has particular physical restrictions for utilize.

On the off chance that you are searching for something more exact, a FeNi split center transformer makes a decent showing with regards to. These offer better measuring execution, even under little current conditions. Be that as it may, they are likewise more costly. FeNi split core transformers additionally battle with linearity and consume up more room in your board and office.

Ferrite split core current transformers are another choice for those searching for a split center transformer arrangement. Ferrite transformers have made some amazing progress in the course of recent years so as to make a superior, more exact observing arrangement. The more up to date ferrite transformers have enhanced penetrability and can be utilized as a part of an extensive variety of energy checking applications, supplanting both FeSi and FeNi transformers, even with a low attractive immersion level. They give a financially savvy other option to FeSi and FeNi transformers.

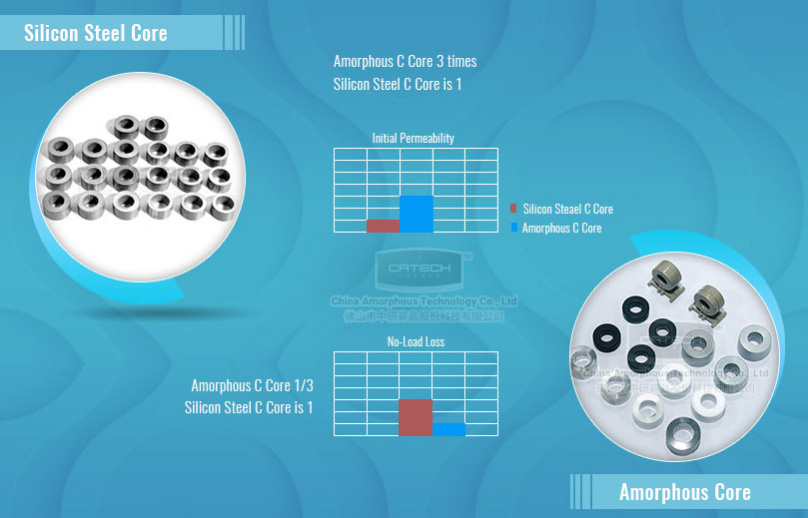

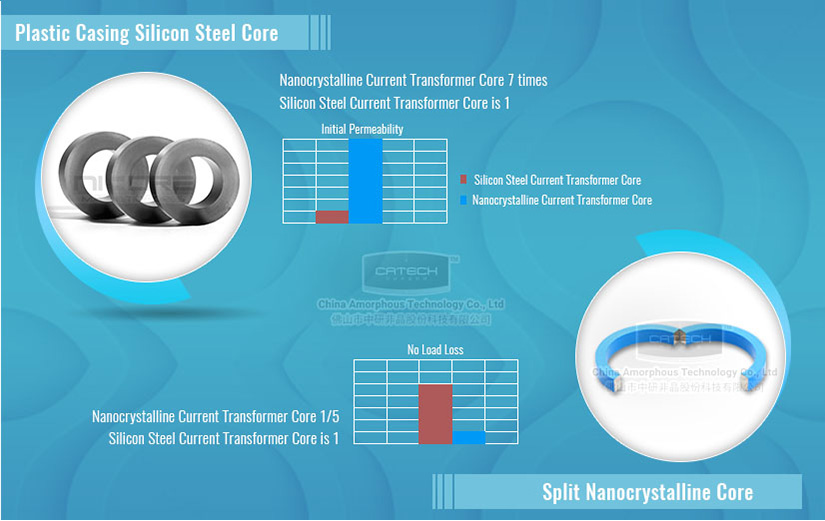

Are you searching for a quality and best current transformers core manufacturing company. please visit CATECH.

CATECH is the wholesale and retail global supplier of split core in China

Go here for a full review of Split Core China

See Related Stories

- http://emicore.weebly.com/

- http://currenttransformercore.blogspot.com/

- https://commonmodecore.wordpress.com/

- https://medium.com/@catechchina/amorphouscore-1387f3b55c5e

Also Read: